Port operators order ‘full steam ahead’ for supersized ships

We’ll send you a myFT Daily Digest email rounding up the latest Supply chains news every morning.

Casting off: A tourist watching the Ever Ace leaving the port of Felixstowe in September © Chris J. Ratcliffe/BloombergTwo months ago, the world’s largest container ship, the Ever Ace, arrived at Felixstowe Harbour, on the east coast of England on its maiden voyage. It had taken the vessel, which has a capacity of 23,992 containers, two months to crawl from Qingdao, eastern China, to the Suffolk port. It delivered goods, including computers, games, clothing and food — and then picked up a large number of empty containers to take back to China.

These vast new ships require supersized infrastructure, as the grounding of the Ever Ace’s sister ship in the Suez Canal, earlier this year, has shown. That can require expansion in the docks where the ships berth, the dredging of channels to provide access, as well as improvements to roads, heightened bridges and wider canals.

At Felixstowe, some of the berths had already been widened and the local Harwich Haven Authority has started work on deepening the channel, at a cost of £120m by 2023.

But, if the need to adapt ports to the new mega ships was evident before Covid-19, the supply chain blockages caused by the pandemic have brought fresh urgency to the need for port modernisation and automation.

“The pandemic has shown us how vulnerable the supply chain is and how we have lagged [behind] in using technology to increase preparedness for any kind of disruption such as this,” says Christian Roeloffs, chief executive of Container xChange, which provides an online platform for the industry to buy, sell and lease shipping containers.

Covid-19 border restrictions, social distancing requirements, and factory closures all wreaked havoc on traditional supply chains, leading to soaring freight rates on the main shipping routes between China, the US, and Europe.

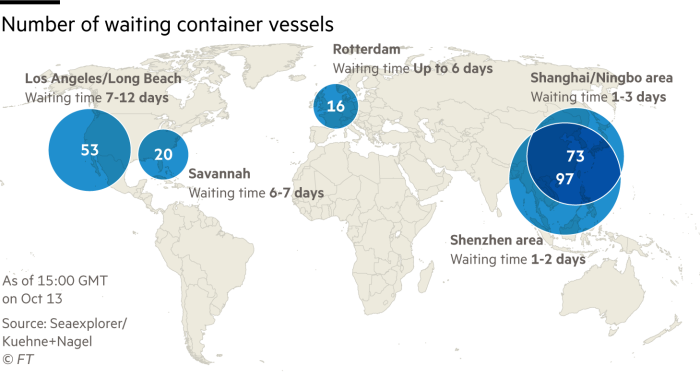

A continuing logjam of ships outside ports and a shortage of truck drivers on land have since caused stock shortages and delays to deliveries — raising prices and frustrating consumers at a time when a pandemic-led boom in online shopping has increased demand for next-day delivery.

Analysis shows inconsistent — sometimes negative — productivity gains from automation

In many cases, the problems have been compounded by lack of automation and outdated labour practices at ports, says John Manners-Bell, chief executive of Transport Intelligence, a consultancy. This is particularly true on the West Coast of the US at the Los Angeles-Long Beach port complex, where a record 76 ships had to remain at sea waiting to unload in September. In China, many ports operate round the clock. By contrast, many in the US operate just 112 hours a week, with days off.

But analysts say that automation could make port services more efficient and safe, cut labour costs by 40 to 70 per cent, as well as reduce carbon dioxide emissions.

The automation of container terminals first started in the early 1990s in Rotterdam, in the Netherlands, where they used unmanned gantry cranes and automated guided vehicles. Now, nearly 40 partly or fully automated container terminals operate around the world, according to Roeloffs.

Shanghai’s Yangshan Deep Water Port can handle more than 40m containers a year © BloombergOne of the biggest terminal developments is Shanghai’s Yangshan Deep Water Port in eastern China, which opened three years ago and can handle more than 40m containers a year. It replaced an army of workers with bridge cranes, auto-guided vehicles, and rail-mounted gantry cranes — all of which can be driven from a control room at a distance.

Other Asian countries are following suit. In Singapore, the Tuas Mega Port — scheduled to open in stages — will be one of the biggest and most automated in the world. Its technology innovations include unmanned vehicles, drones, data analytics, and driverless trucks for port transport. Digital platforms will also be employed to reduce port congestion and bureaucracy.

However, while the pandemic has highlighted the need for modernisation, it has also underscored its limits.

Although China has some of the largest and most modern ports in the world, Beijing’s tough approach to Covid in the workforce means port operations have been shut down frequently, says Manners-Bell.

This has caused significant congestion on the land side as containers stack up waiting to be loaded and ships are left at anchorage outside key ports, such as Ningbo and Yantian.

Furthermore, the new technologies that must be acquired to save on labour costs are also still expensive.

Tuas Mega Port in Singapore © BloombergA report by the rating agency Moody’s in 2019 questioned the high capital investment cost required, warning of uncertain productivity gains, disruption to operations, and the political risk posed by potential conflict with unions.

“Many analyses that compare productivity metrics between automated and conventional terminals indicate inconsistent and, in a number of cases, negative productivity gains from automation,” Moody’s said.

There are also questions over who should pay for infrastructure improvements, especially in cases where the ports are privately owned. In the UK, for example, most ports are owned by consortiums of private equity, sovereign wealth and offshore funds.

Environmental concerns have added to this debate. This month, the UK Major Ports Group, a trade association for the UK’s largest port operators, called on the government to establish a dedicated “green ports fund” to invest in green infrastructure, alongside the industry.

Such infrastructure could include electrical charging points for ships in ports and the new generation of electric- and hydrogen-powered equipment that could help ports meet the UK government’s net zero targets.

{"focus":["cbab3e00-707c-453f-ac54-b2d0ddb7e1e9","c2e0d6ac-e37a-4785-b179-8c132142ea08","59d55e5c-cb83-49dc-bacb-26dcc51566d0","06610896-2754-4847-a48f-9363d18a8c5e","654b7bcf-bef1-428e-92b2-3be7713ce3fa","d1252624-8645-438b-b521-9244aebdc99e","0e0fb46c-1140-41de-9d74-43359741a083","6c0db9d6-0114-49ed-96d6-42d48e8b527e","6b683eff-56c3-43d9-acfc-7511d974fc01","c47f4dfc-6879-4e95-accf-ca8cbe6a1f69","29e67a92-a3b8-410c-9139-15abe9b47e12","ec4ffdac-4f55-4b7a-b529-7d1e3e9f150c","82645c31-4426-4ef5-99c9-9df6e0940c00","56cd81a5-6bdc-4296-a288-796ce13e4055","6cc4c4ed-ef61-4c71-a5bb-f454fb5010a8"],"authorConcepts":["44b8a9c4-4b63-44eb-bc02-60e9882bdf3b"],"displayConcept":"59d55e5c-cb83-49dc-bacb-26dcc51566d0"}Get alerts on Supply chains when a new story is published

Get alertsCopyright The Financial Times Limited 2021. All rights reserved.Reuse this content (opens in new window) CommentsJump to comments sectionPromoted ContentExplore the Special ReportREAD MOREFuture of LogisticsPort operators order ‘full steam ahead’ for supersized ships2 hours ago

- Currently reading:Port operators order ‘full steam ahead’ for supersized ships

- Robotics supply helping hand to speedy order fulfilment

- Distribution groups grapple to reduce their carbon footprints

- Euston trial shows appeal of letting the train take the strain

- Florist peddles pedals for flower power to tackle congestion

- Long hours and stagnant pay create transport bottlenecks

- Vaccine distributors go the extra mile to help remote populations

- Industrial goods Add to myFT

- Container shipping Add to myFT

- Supply chains Add to myFT

- UK infrastructure Add to myFT

- Gill Plimmer Add to myFT

Owl Media Group takes pride in providing social-first platforms which equally benefit and facilitate engagement between businesses and consumers and creating much-needed balance to make conducting business, easier, safer, faster and better. The vision behind every platform in the Owl Media suite is to make lives better and foster a healthy environment in which parties can conduct business efficiently. Facilitating free and fair business relationships is crucial for any thriving economy and Owl Media bridges the gap and open doors for transparent and successful transacting. No advertising funds influence the functionality of our media platforms because we value authenticity and never compromise on quality no matter how lucrative the offers from advertisers may seem.

Originally posted on: https://www.ft.com/content/e8a87a67-3877-4fe9-8a5e-3322a58d43b0

Casting off: A tourist watching the Ever Ace leaving the port of Felixstowe in September © Chris J. Ratcliffe/Bloomberg

Casting off: A tourist watching the Ever Ace leaving the port of Felixstowe in September © Chris J. Ratcliffe/Bloomberg Shanghai’s Yangshan Deep Water Port can handle more than 40m containers a year © Bloomberg

Shanghai’s Yangshan Deep Water Port can handle more than 40m containers a year © Bloomberg Tuas Mega Port in Singapore © Bloomberg

Tuas Mega Port in Singapore © Bloomberg